Thermal-mass Gas Metering Proven for Years, Certified for The Future

- Time of issue:2021-10-08 16:27:35

- Views:

Thermal-mass Gas Metering Proven for Years, Certified for The Future

- Time of issue:2021-10-08 16:27

- Views:

Thermal-mass technology is a proven means for measuring the flow of gases and liquids. The recent technological advances and miniaturisation have enabled the use of the technology for high-volume, cost-sensitive applications such as natural gas metering.

Two studies published in 2021 now also confirm the long-term reliability of this technology for applications in harsh environments. The studies investigated thermal-mass gas meters following operation in the field for up to over 10 years. They concluded that all meters were operating well within the accuracy limits prescribed during service and that the majority of meters still fulfilled the requirements for brand-new gas meters.

Coupled with the release of a dedicated European standard in 2021 (EN 17526), thermal gas technology is, therefore, a cost-effective, proven and reliable solution for gas metering that is already powering millions of gas meters worldwide. Additionally, it offers extensive self- and network-diagnostic capabilities and is ready for a wide range of natural gas compositions including hydrogen blends and pure hydrogen.

Thermal-mass measurement principle

For the past 80 years, thermal-mass technology has been used for measuring flow in the most critical applications such life-sustaining medical ventilation, air intake regulation in car combustion engines, building ventilation systems and control of sensitive industrial processes. The thermal mass measurement principle is the most versatile and robust way to measure flow.

Until recently, however, it was prohibitively expensive for high-volume, price-sensitive applications. With the progress of MEMS (microelectromechanical system) technology, the thermal-mass flow measurement principle has been realised on a single silicon chip. Highly integrated CMOS processing of such chips allows for effective miniaturisation and high-volume production. With these advances, the cost of thermal-mass technology has been radically reduced to the point where it is an attractive solution not only for high-end applications but also for low-cost, high-volume devices such as disposable flow sensors and gas meters.

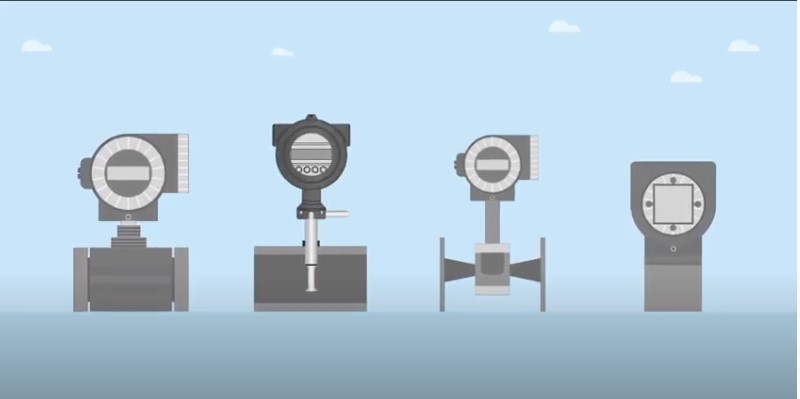

Thermal-mass technology for gas metering

The application of thermal-mass technology in gas metering was pioneered by Sensirion in the early 2000s. The main benefits of this implementation are excellent accuracy, compact size, ultra-low power consumption (critical for battery-powered gas meters) and, above all, a very attractive cost. The latter is made possible by the integration of the flow sensor, signal processing and analysis electronics, and calibration data storage in a single semiconductor chip. Apart from the flow, thermal-mass sensors can also readily measure various thermal properties of the gas to compensate for variations in gas composition.

This makes thermal-mass gas meters an ideal choice for measuring consumption of natural gases with a very wide composition range as well as for gas blends with hydrogen or even pure hydrogen.

The first thermal-mass gas meters were installed in the field in 2007. Following an initially slow adoption of the technology, the rollout has significantly accelerated in recent years and to date over 6 million gas meters worldwide rely on this proven way to measure gas flow. The main factor that initially limited the adoption of the technology was the perceived lack of track record in the field. Even though thermal-mass technology had been proven over the years in many other applications, it was a relative newcomer to the gas metering industry – an industry that values robust performance, safety and reliability above all else. Various national and international standards regulate the required accuracy of gas meters. Different accuracy classes exist, with class 1.5 being the most widely used worldwide.

OIML R137 and EN 17526 (the dedicated thermal-mass gas metering standard being published in 2021) define the maximum permissible error (MPE) for temperature-compensated class 1.5 gas meters (such as thermal-mass meters) as 2% and 3.5% at high and low flow regimes, respectively.

OIML R137 additionally prescribes 2x MPE (3.5% / 6.5%) for meters that have been remeasured following in-field service. Hence, the 2x MPE is widely accepted as the bar that a meter has to clear while in service (typically 10–15 years).

Field studies of reliability of thermal-mass gas meters

By 2021, a significant number of thermal mass gas meters had already been operating in the field for over a decade.

Two independent studies recently looked at how different types of thermal-mass meters perform after having been operated in gas for up to over 10 years. The first study, conducted by NMi – a Dutch notified body – looked at industrial G10, G16 and G25 meters manufactured by MeteRSit and installed in Italy between 2013 and 2016. The institute randomly selected 20 meters from a list of the 2,749 available. These were later collected by the manufacturer (19 meters – one was installed in an inaccessible location) and sent to NMi for read-back measurement. The said measurement involved measuring each meter both in air and natural gas between Qmin and Qmax flow rates. It was found that all meters, regardless of the number of years in service and accumulated measured gas volume, were still well within the 2x MPE allowed. Additionally, all meters performed within 1x MPE in gas, and 15 of the 19 meters also in air. That is to say, most of the meters performed as well as brand-new devices.

The second study involved 35 “EGZ” G4 residential meters that were built by ABB and installed in Switzerland between 2010 and 2011. These meters were operated for 9 to 10 years before being removed from the field and remeasured. The study was performed by MEMS AG, whose measurement infrastructure was certified by the Swiss Federal Institute of Metrology, METAS, in preparation for the investigation. Again, the authors measured all meters between Qmin and Qmax flow rates both in air and natural gas. Similar to the study conducted by NMi, all meters measured performed well within 2x MPE in both air and gas. Additionally, all 35 meters were still within 1x MPE when tested in gas, and 31 of the 35 also in air.

Of the 35 meters measured, 3 were installed in a pressure reduction station and experienced unusually high flow rates. In fact, they accumulated measured volumes approximately 14 times higher than the other 32 meters (280 000 m3 vs 20 200 m3 over 10 years). It would take an average meter 140 years of operation to accumulate such an amount of gas measured. Importantly, all 3 meters were still within 1x MPE for both air and natural gas – a benchmark for new gas meters. What the two studies had in common was that the tested gas meters were based on the key metrological units manufactured by Sensirion AG: CMOSense® gas metering modules. They also both confirmed that thermal-mass gas meters are still as good as new after over 10 years of operation in the field.

Even if the errors were to double over the next 10 years of operation (of which there is no indication), the meters would still be within the 2x MPE allowed by OIML R137.

Hence, one can conclude that thermal-mass meters demonstrate the ability to operate reliably in the field for over 20 years. This is significantly longer than the lifetime of a typical gas meter. The metrological unit appears even more stable than that, given that it is unaffected by the very high volume of gas measured (14x the average). It can thus be concluded that it would easily outlive the other parts of the meters.

EN 17526: new thermal-mass gas metering standard

The maturity of thermal-mass technology for gas metering applications has been recognised by CEN with the publication of a dedicated European standard in 2021. “EN 17526. Gas meters. Thermal-mass flowmeter based gas meter” outlines the requirements and tests needed to bring thermal-mass gas meters into the field. It is a harmonised standard, meaning that it builds on the normative documents previously developed for the diaphragm and ultrasonic gas meters. It is also compatible with international norms such as OIML R137. Meter manufacturers used to the existing standards should not find any surprises in the new thermal mass norm. From now on, the dedicated thermal-mass gas metering standard will remove a significant uncertainty previously associated with certifying such meters because the requirements and test plans are clearly laid out in the dedicated standard.

Thermal-mass gas metering: proven for years, certified for the future

Recent developments have brought the cost of thermal-mass technology to the point where it has emerged as a very attractive solution for gas metering applications. Long-term field reliability studies indicate that the lifetime of thermal-mass gas meter modules is significantly longer than the design life of a typical gas meter. The publication of a dedicated thermal-mass gas metering standard in 2021 recognises the maturity of the technology and paves the way to more widespread adoption of this well-proven method for flow measurement in the gas metering industry. In addition to attractive cost, reliability and very compact size, thermal-mass technology also offers extensive self- and network-diagnostic capabilities (e.g. air recognition for tampering detection). Finally, the technology can readily cope with measuring natural gas with a very wide composition range, as well as natural gas-hydrogen blends of any concentration and pure hydrogen.

Source: Smart Energy International

Relevant Information

Zhengzhou Anran I&C Technology Co.,Ltd.

Tel: 0086-371-68629564

E-mail: global.sales@zzanran.com

Address: The National University Science Park, No.11, Changchun Road, High&New Technology Development District, Zhengzhou

Copyright Zhengzhou Anran I&C Technology Co., Ltd.

0086-371-68629564

0086-371-68629564

Message

Message